What are phase change materials?

Phase Change Materials & Phase Change Technology

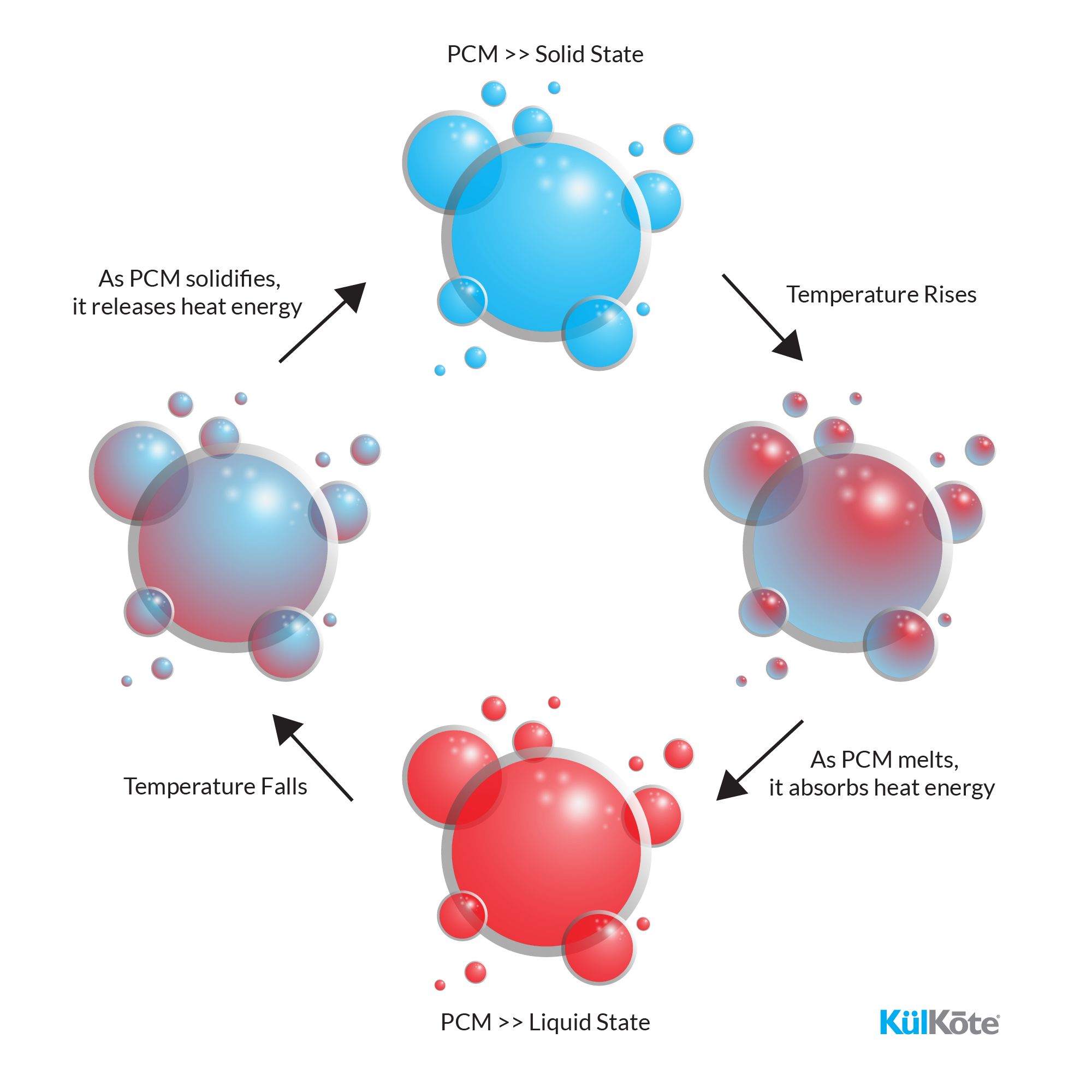

Phase change materials (PCMs) are substances that absorb and release thermal energy during the process of melting and solidifying. When a PCM melts, it absorbs a large amount of heat (energy) from the environment. Conversely, when a PCM solidifies it releases a large amount of energy in the form of latent heat. PCMs continuously cycle through this process, making them ideal for a variety of everyday applications that require temperature management. PCMs reduce temperature swings and have the ability to maintain a specific temperature for extended periods of time.

PCMs are used in many industries including building/construction, refrigeration, HVAC, thermal energy storage, textiles, and electronics. PCMs are used in these applications because they are eco-friendly and energy-saving. Some PCM applications include:

- High-performance textiles and foams that provide relief from hot and cold conditions.

- Refrigerators and freezers that use less energy.

- Shipping containers that maintain goods at the desired temperature for longer periods.

- Construction material that keeps living spaces comfortable and reduces heating and cooling costs.

There are many PCM products that are designed for a wide range of temperatures. They vary from negative 50 degrees Celsius to higher than 150 degrees Celsius. PCM products can store up to 15 times more heat per volume compared to water and rocks. For human contact, generally the best PCMs activate at around 28 degrees Celsius to provide the most comfortable conditions.

A PCM works because of two different forms of heat energy: latent and sensible heat. Latent heat is the amount of energy that is needed to change matter from one state to another. For example, a liquid to a solid. The most common example of this type of heat energy is an ice cube. An ice cube will use the latent heat capacity and absorb the heat energy that is coming from the drink. When the ice cube has melted it is because it absorbed all of the latent energy that it is capable of. On the other hand, sensible heat is the amount of energy needed to alter the temperature of a substance without changing the phase of the substance. An example of this is a water heater. When latent and sensible heat work together, they are able to maintain the specific temperature that is needed for an extended period of time.

Lastly, PCM products last typically last for the lifetime of the product they are used in or applied to. Over the course of the melting and solidifying cycles, the transition temperature and latent heat energy should remain the same. Additionally, the PCM is encapsulated by a shell to prevent leakage, degredation, and contamination.

See the scientific proof or view the key advantages of KulKote.